Spill Pallet / Rackable Plastic Pallet / Stackable Plastic Pallet / Nestable Plastic Pallets - WELLGUARDING

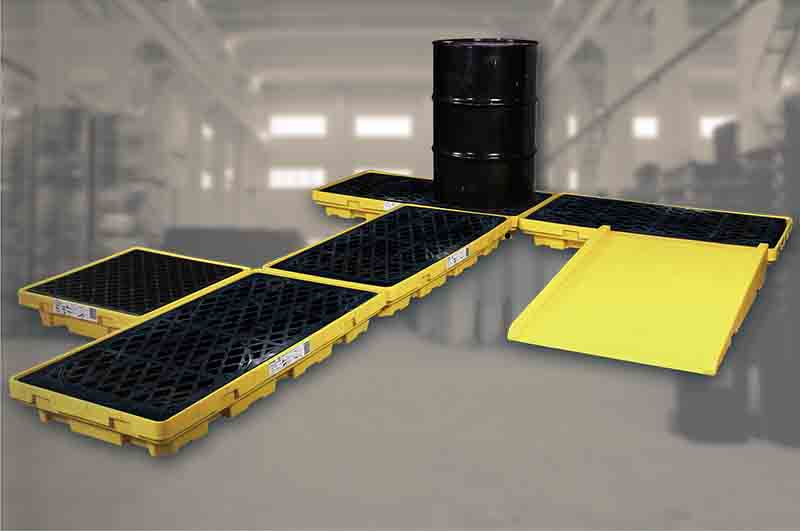

Oil Drum Spill Containment Pallet

Spill pallet for easily controlling chemical leakage

Hazardous chemicals leakage is a major hidden danger to the environmental safety of the workplace, and it also brings huge harm to the ground water and the overall environment, the cost

of treatment is high. Wellguard Spill pallets and decks series products help you keep the environment of storage areas such as oil drums and chemical drums clean, effectively prevent and control pollution caused by oil and chemical leakage, solve your problems in time, and easily cope with accidental leakage.

Spill pallets’ advantages and features

1) Strong structure can carry full load oil drums, chemical drums, various storage containers and mechanical equipment.

2) Polyethylene material, anti-ultraviolet, anti-rust, anti-corrosion, can resist most chemicals;

3) The anti-slip grille on the orange peel surface will not fracture under full load and can be removed, which is beneficial to quickly handle the leaking liquid;

4) Pallet can be transported by forklift, and the platform can be leaned together to form a leaking workstation;

5) To keep the ground dry, avoid slipping and falling accidents;

6) All spill pallets and decks can be nested and stacked, saving space and transportation costs;

2 drum spill pallets with stackable structure save space and transportation costs

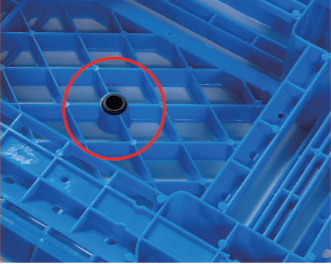

hexagonal drain plug facilitates drainage

2-drum and 4-drum spill pallets with stackable structure save space and transportation costs

2-drum and 4-drum spill pallets have forklift slots for convenient forklift operation to improve efficiency (*forklift overload prohibited)

hydraulic carrying vehicles can also be used to move pallets, which is more convenient

poly spill pallet ramps make it easier to move large articles

Poly Spill Decks

The poly spill deck is lower than the pallet, thus saving the space, improving the safety, efficiency and facilitating handling of oil drums and chemical drums. Generally, the poly spill deck is used for storing oil drums, chemical drums,etc, instead of transferring such containers. When installed in a workshop, the spill deck can be used for various operations (oil extracting, filling and separating, etc.), as a platform. It is also equipped with the same grate and drain holes. Various decks can be assembled to form a stable and reliable workstation.

WLPP001

WLPP001

WLPP004

Poly Spill Deck |

Name | 200L Drum quality | Capacity (Gal/L) | Static Loading (Kgs) | Dynamic Loading (Kgs) | Gross Weight | Ext.Dimensions (H*L*W/cm) | Forklift | Model |

| Labratory desktop spill deck | / | 4L

| 50

| /

| 0.7 | 33.5x33.5x5.8

| N/A | WLPP001A |

| Labratory desktop spill deck | / | 10L

| 100

| /

| 1.2 | 49x35x9.5

| N/A | WLPP001B |

| Labratory desktop spill deck | / | 20L

| 200 | /

| 1.8 | 66x36x12

| N/A | WLPP001C |

1 drum spill deck | 1 | 11/42 | 1000 | 300 | 8.15 | 68x68x15 | N/A | WLPP001 |

1 drum spill deck | 1 | 9/28 | 1600 | 800 | 6.5 | 72x72x16 | 2 way | WLPP001-1 |

| 1 drum spill deck-economy | 1 | 40L

| 1000

| 300 | 7 | 68x68x15 | 2 way | WLPP001-2 |

| 2 drum spill deck | 2 | 21/80 | 2000 | 600 | 18.5 | 130x66x15 | N/A | WLPP002 |

| 2 drum spill deck | 2 | 21/80 | 2000 | 500 | 14.5 | 130x68x15 | 2 way | WLPP002-1 |

| 2 drum spill deck-economy | 2

| 35L

| 2000

| 400 | /

| 120*62*10 | N/A

| WLPP002-5 |

| 2 drum spill deck-economy | 2

| 80L | 2000

| 400 | / | 130x68x15 | 2 way | WLPP002A |

4 drum spill deck | 4 | 40/150 | 4000 | 1000 | 32 | 130x128x15 | N/A | WLPP004 |

4 drum spill deck | 4 | 34/120 | 4000 | 1000 | 32 | 130x130x15 | 4 way | WLPP004A |

4 drum spill deck | 4 | 48/180 | 4000 | 1000 | 22.5 | 128x128x17 | 4 way | WLPP004B |

| 4 drum spill deck | 4 | 24/90 | 4000 | 1000 | 20 | 121x121x17 | 4 way | WLPP004C |

4 drum spill deck-small

| 4 | 65L

| 3000

| 800 | /

| 120*120*10 | 4 way | WLPP004C-1 |

| 4 drum spill deck-economy | 4 | 120L

| 3000

| 800 | / | 130x130x15 | 4 way | WLPP004A-1 |

Poly spill pallets

The spill pallet is essentially a plastic pallet which can control the leakage and has a leak-holding groove. The forklift tank is set to store, transport, and turnover oil drums and chemical drums; all leakage will flow into the tank. The spill pallet has its own matching slope, which makes the handling of chemical storage barrels easy, fast and simple. The high-strength,movable and detachable grille is convenient to disassemble,clean and replace, and the drain hole can discharge the liquid in the drain tank, so that most of the liquid can be recycled.The upgraded version of the four-barrel pallet is provided with forklift grooves of 550mm and 650mm width on the longitudinal side, which provides convenience for customer operations. There are stacking limits around the pallets to facilitate accurately stack multiple pallets and package them for transportation, which is convenient for forklift transfer,maximizes space savings and transportation costs saving.

WSP002

WSP004

Poly Spill Pallet |

|

|

Name | 200L Drum quality | Capacity (Gal/L) | Static Loading (Kgs) | Dynamic Loading (Kgs) | Gross Weight | Ext.Dimensions (H*L*W/cm) | Forklift | Model |

| 2 drum spill pallet | 2

| 24/90 | 2000

| 800 | 12

| 128x68x17

| 2 way | WLPP002-3 |

| 2 drum spill pallet | 2

| 11/45 | 2000

| 500 | 10.5

| 128x62x17

| 2 way | WLPP002-4 |

2 drum spill pallet | 2 | 32/120 | 2000 | 600

| 20.5

| 130x66x30 | 2 way | WSP002 |

| 2 drum spill pallet | 2 | 32/120 | 2000 | 600

| 22

| 130x68x30 | 2 way | WSP002A |

| 2 drum spill pallet-economy | 2 | 120L

| 1500

| 500 | /

| 130x68x30 | 2 way | WSP002B |

IBC spill pallet

| 1 IBC drum

| 58/200

| 4000

| 1000 | 28

| 130x110*30

| 4 way

| WSP003 |

| IBC spill pallet-economy | 1 IBC drum | 150L

| 3500

| 900 | /

| 125*105*17

| 4 way | WSP003-1 |

4 drum spill pallet | 4 | 70/260 | 4000 | 1000

| 33 | 130x130x30 | 4 way | WSP004A |

| 4 drum spill pallet | 4 | 70/265 | 4000 | 1000

| 38 | 130x128x30 | 4 way | WSP004 |

| 4 drum spill pallet-economy | 4 | 70/260 | 4000

| 1000 | /

| 130x130x30 | 4 way | WSP004A-1 |

Poly spill decks(H:200mm)

By adopting the reinforced structure design, the spill decks is featured with high load bearing capacity, high safety and high stability. The decks accurately restricts the gratings on the periphery, thereby facilitating easy installation, removal and cleaning of the gratings. Meanwhile, the gratings for PE decks are highly robust and corrosion resistant and have undergone surface roughening to effectively enhance surface friction,thus ensuring stable storage of drums. Moreover,holes in the gratings can effectively avoid possible accidental splash of dangerous chemicals during filling, subpackaging or storage.

WLPP002-2

WLPP004-2

Poly Spill Deck |

|

|

Name | 200L Drum quality | Capacity (Gal/L) | Static Loading (Kgs) | Dynamic Loading (Kgs) | Gross Weight | Ext.Dimensions (H*L*W/cm) | Forklift | Model |

| 2 drum spill deck | 2 | 27/100 | 2000 | 600 | 21 | 132x68x15 | 2 way | WLPP002-2 |

4 drum spill deck | 4 | 24/90 | 4000 | 1000 | 31.5 | 131x131x16 | 4 way | WLPP004-2 |

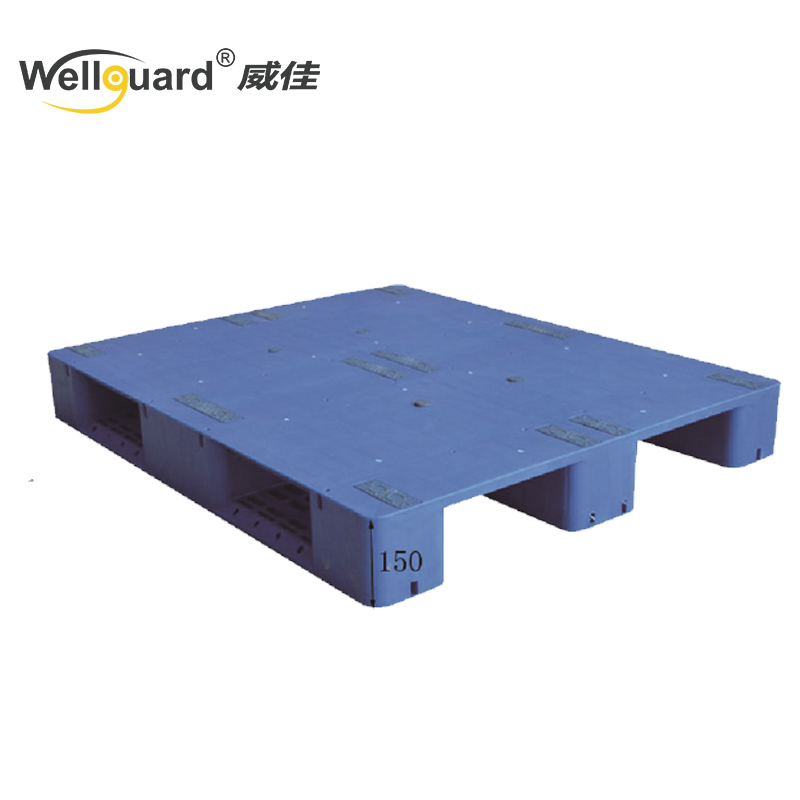

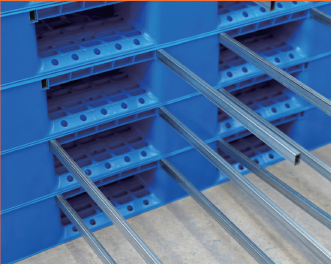

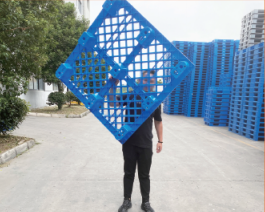

Rackable Plastic Pallets

Rackable Plastic Pallets refer to pallets suitable for use on shelves. They can be used on shelves with different structures such as beam shelves, drive-in shelves, and automated three-dimensional warehouses. Of course, they can also be used on flat ground. Rackable Plastic Pallets have a relatively large load capacity. Generally, the dynamic load can reach 1500kg, and the dynamic load can reach 6000kg. It can also reach 800-1000kg on the shelf, so it is more suitable for placing heavier products. Rackable Plastic Pallets have different forms such as 6-runners grid plastic pallet, 3-runners grid plastic pallet, double sided grid plastic pallet, 6-runners flat plastic pallet, 3-runners flat plastic pallet, double sided flat plastic pallet, etc., suitable for different Users use, but the most commonly used is the 3-runners grid plastic pallet.

3-Runners Grid plastic pallet

3-Runners Grid plastic pallet |

Names | Numbers of Steel pipe | Dynamic loading(kg) | Static loading(kg) | Dimension (L*W*H/cm) | Forklift | Model |

1008-3 Runners Grid pallet | 8 | 1000 | 4000 | 100x80x15 | 4 WAY | WGPP1008NC |

1111-3 Runners Grid pallet | 8 | 1000 | 4000 | 110x110x15 | 4 WAY | WGPP1111NC |

1208-3 Runners Grid pallet | 8 | 1000 | 4000 | 120x80x15 | 4 WAY | WGPP1208NC |

1210A-3 Runners Grid pallet | 8 | 1000 | 4000 | 120x100x15 | 4 WAY | WGPP1210ANC |

1210C-3 Runners Grid pallet | 8 | 1000 | 4000 | 120x100x16 | 4 WAY | WGPP1210CNC |

1212-3 Runners Grid pallet | 10 | 1000 | 4000 | 120x120x16 | 4 WAY | WGPP1212NC |

1311-3 Runners Grid pallet | 8 | 1000 | 4000 | 130x110x15 | 4 WAY | WGPP1311NC |

1412-3 Runners Grid pallet | 8 | 1000 | 4000 | 140x120x15 | 4 WAY | WGSP1412NC |

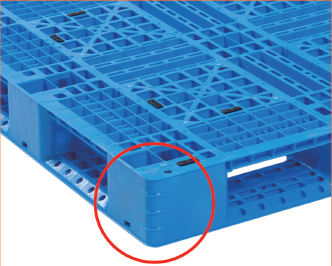

3-Runners Grid plastic pallet’s advantages

Rounded corner design to prevent bumps

Rounded column leg design, cushioned when dropped

Function, anti-collision prolongs the service life of the pallet during forklift operation

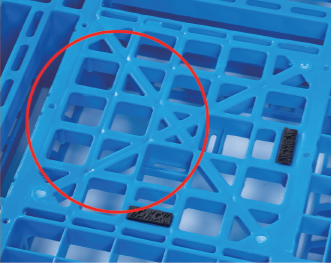

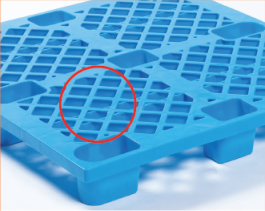

Grid hollow design

The hollow design on the surface is beneficial to the waterproof and moisture-proof of the goods, and ensures that the bottom of the goods is in a ventilated state

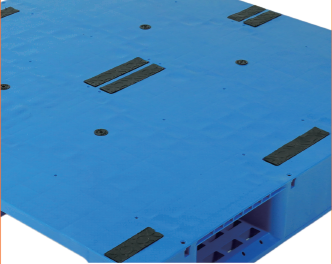

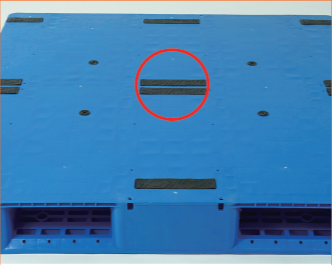

Pallet face non-slip pad design

Make the surface of the pallet contact with the goods with good friction to prevent the goods from slipping out of the pallet

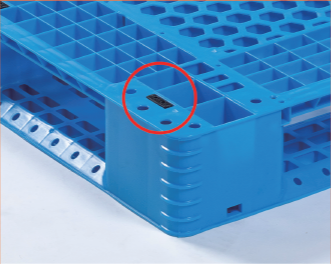

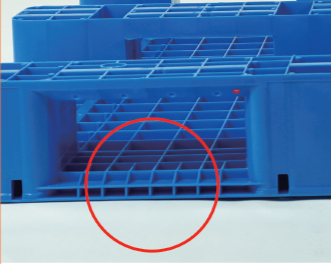

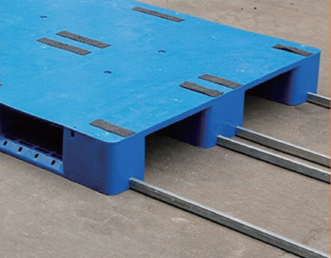

Can add steel pipe design

Can add steel pipe design to meet different bearing requirements

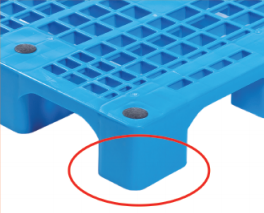

Anti-skid pad design at the bottom of the pallet

When the pallet is in contact with the ground or the shelf, it has friction, so that the pallet is stable on the ground or

Not easy to fall off on the shelf

Suitable for a variety of shelves and flat use

3-Runners Grid plastic pallet have high carrying capacity

Easy to use forklift

Not only can it be used for turnover on flat ground, it can also be used on shelves with different structures such as beam-type shelves, drive-in shelves, automatic three-dimensional warehouses, etc.

3-Runners Flat plastic pallet

3-Runners Flat plastic pallet |

Names | Numbers of Steel pipe | Dynamic loading(kg) | Static loading(kg) | Dimension (L*W*H/cm) | Forklift | Model |

1012-3 Runners Flat pallet | 8 | 1500 | 6000 | 100x120x15 | 4 WAY | WGSP1012PC |

1109-3 Runners Flat pallet | 8 | 1000 | 4000 | 110x90x17 | 4WAY | WGSP1109PC |

1111-3 Runners Flat pallet | 8 | 1500 | 6000 | 110x110x15 | 4 WAY | WGSP1111PC |

1208-3 Runners Flat pallet | 8 | 1500 | 6000 | 120x80x15 | 4 WAY | WGSP1208PC |

1210A-3 Runners Flat pallet | 8 | 1500 | 6000 | 120x100x15 | 4 WAY | WGSP1210APC |

1210B-3 Runners Flat pallet | 8 | 1500 | 6000 | 120x100x17 | 4WAY | WGSP1210BPC |

1212A-3 Runners Flat pallet | 8 | 1500 | 6000 | 120x120x17 | 4WAY | WGSP1212APC |

1212B-3 Runners Flat pallet | 8 | 1000 | 4000 | 120x120x15 | 4WAY | WGSP1212BPC |

1311-3 Runners Flat pallet | 8 | 1500 | 6000 | 130x110x17 | 4WAY | WGSP1311PC |

1312-3 Runners Flat pallet | 8 | 1500 | 6000 | 130x120x16 | 4WAY | WGSP1311PC |

1616-3 Runners Flat pallet | 8 | 1000 | 4000 | 160x160x15 | 4WAY | WGSP1616PC |

Flat plastic pallet’s advantages

Smooth flat design

The smooth surface looks clean and easy to clean, and the surface is burr-free. The smooth surface will not damage the goods and is not easy to scratch when used.

Ribs on the edges increase the load bearing

The double-reinforced tray with upper and lower layers of ribs is evenly stressed and bears better load.

Pallet face non-slip pad design

Make the surface of the pallet contact with the goods with good friction to prevent the goods from slipping out of the pallet.

Can add steel pipe design

Meet different bearing requirements

Smooth foot design

The smooth foot surface is designed to pass the assembly line, which is convenient and not easy to bump

Smooth Bottom Design

The appearance is clean and easy to clean The bottom surface is burr-free and not easy to scratch

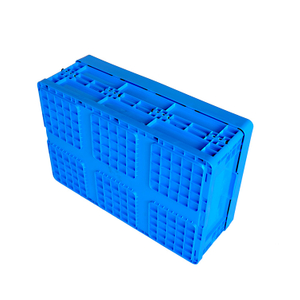

Stackable Plastic Pallets

Double-sided plastic pallets are the common structure of Stackable Plastic Pallets. As the name suggests, a double-sided pallet refers to a pallet that can be used on both sides. Compared with other structural pallets, the main function of double-sided plastic pallets is to store goods. Double-sided pallets are widely used in the chemical industry. In addition, double-sided plastic pallets are usually used in conjunction with palletizers, and are often used to palletize goods. It is more common in deep-processing industries such as food, beverages, and flour.

6-Runners Grid plastic pallet

6-Runners Grid plastic pallet |

Names | Numbers of Steel pipe | Dynamic loading(kg) | Static loading(kg) | Dimension (L*W*H/cm) | Forklift | Model |

1111A-6 Runners Grid pallet | 0 | 700 | 3000 | 110x110x15 | 4 WAY | WGPP1111ANT |

1111-6 Runners racking pallet | 7 | 1000 | 4000 | 110x110x15 | 4 WAY | WGSP1111NT |

1208-6 Runners racking pallet | 7 | 1000 | 3000 | 120x80x15 | 4 WAY | WGSP1208NT |

1208-6 Runners Grid pallet | 0 | 1000 | 3000 | 120x80x13.5 | 4 WAY | WGPP1208NT |

1210A-6 Runners Grid pallet | 0 | 700 | 3000 | 120x100x15 | 4 WAY | WGPP1210ANT |

1210-6 Runners racking pallet | 7 | 1000 | 4000 | 120x100x15 | 4 WAY | WGSP1210NT |

1212-6 Runners Grid pallet | 7 | 1000 | 4000 | 120x120x15 | 4 WAY | WGPP1212NT |

1311-6 Runners Grid pallet | 7 | 1000 | 4000 | 130x110x15 | 4 WAY | WGPP1311NT |

1411-6 Runners Grid pallet | 7 | 1000 | 4000 | 141x110x15 | 4 WAY | WGPP1411NT |

Double sided Grid plastic pallet

Double sided Grid plastic pallet |

Names | Numbers of Steel pipe | Dynamic loading(kg) | Static loading(kg) | Dimension (L*W*H/cm) | Forklift | Model |

1010 Double sided Grid pallet | 8 | 1000 | 4000 | 100x100x15 | 4 WAY | WGSP1010ND |

1111 Double sided Grid pallet | 8 | 1000 | 4000 | 110x110x15 | 4 WAY | WGSP1111ND |

1210 Double sided Grid pallet | 8 | 1000 | 4000 | 120x100x15 | 4 WAY | WGSP1210ND |

1212A Double sided Grid pallet | 8 | 1500 | 6000 | 120x120x15 | 4 WAY | WGSP1212AND |

1311A Double sided Grid pallet | 8 | 1000 | 4000 | 130x110x15 | 4 WAY | WGSP1311AND |

1412 Double sided Grid pallet | 8 | 1000 | 4000 | 140x120x15 | 4 WAY | WGSP1412ND |

1414 Double sided Grid pallet | 8 | 1500 | 6000 | 140x140x15 | 4 WAY | WGSP1414ND |

1513 Double sided Grid pallet | 8 | 1500 | 5000 | 150x130x15 | 4 WAY | WGSP1513ND |

1515 Double sided Grid pallet | 8 | 1500 | 6000 | 150x150x15 | 4 WAY | WGSP1515ND |

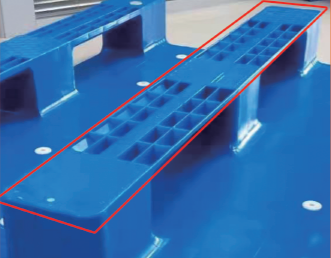

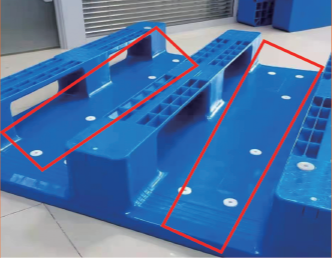

6-Runners Grid plastic pallet’s advantages

Rounded corner design prevents collision

The design of the rounded column legs has a buffering effect when the forklift is in operation. The service life of the pallet is extended.

Grid hollow design

The hollow design on the surface is beneficial to the waterproof and moisture-proof of the goods, and ensures that the bottom of the goods is in a ventilated state.

Pallet face non-slip pad design

Make the surface of the pallet contact with the goods with good friction to prevent the goods from slipping out of the pallet.

Steel tube design

Steel pipes can be added to meet different bearing requirements.

Bottom is cross flat

The structure is stable and not easy to damage

Convenience and secondary stacking of goods

Save storage area.

Bottom non-slip pad design

There is a cargo anti-slip block at the bottom of the pallet, and there is a forklift anti-slip block in the fork hole to enhance the anti-slip performance and make it safer to use.

6-Runners Flat plastic pallet

6-Runners Flat plastic pallet |

Names | Numbers of Steel pipe | Dynamic loading(kg) | Static loading(kg) | Dimension (L*W*H/cm) | Forklift | Model |

1210-6 Runners Flat pallet | 8 | 1000 | 4000 | 120x100x16 | 4 WAY | WGSP1210PT |

1212-6 Runners Flat pallet | 8 | 1000 | 4000 | 120x120x16 | 4 WAY | WGSP1212PT |

1311-6 Runners Flat pallet | 8 | 1000 | 4000 | 130x110x16 | 4 WAY | WGSP1311PT |

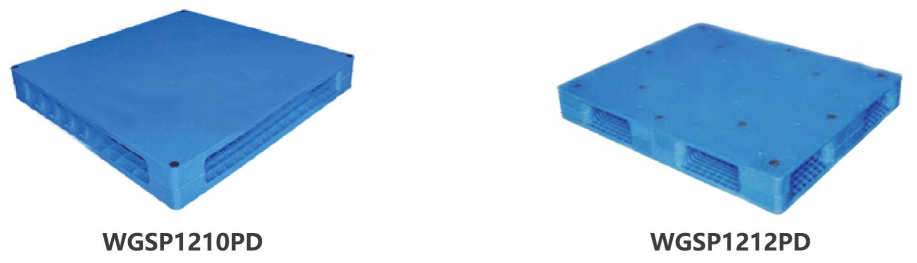

Double sided Flat plastic pallet

Double sided Flat plastic pallet |

Names | Numbers of Steel pipe | Dynamic loading(kg) | Static loading(kg) | Dimension (L*W*H/cm) | Forklift | Model |

1210 Double sided Flat pallet | 8 | 1500 | 6000 | 120x100x15 | 4 WAY | WGSP1210PD |

1212 Double sided Flat pallet | 8 | 1500 | 6000 | 120x120x15 | 4 WAY | WGSP1212PD |

1310 Double sided Flat pallet | 8 | 1500 | 6000 | 130x100x15 | 4 WAY | WGSP1310PD |

1311 Double sided Flat pallet | 8 | 1500 | 6000 | 130x110x15 | 4 WAY | WGSP1311PD |

1313 Double sided Flat pallet | 8 | 1500 | 6000 | 130x130x16 | 4 WAY | WGSP1313PD |

1412 Double sided Flat pallet | 8 | 1500 | 6000 | 140x120x15 | 4 WAY | WGSP1313PD |

1616 Double sided Flat pallet | 8 | 1000 | 4000 | 160x160x16 | 4 WAY | WGSP1313PD |

Flat plastic pallet’s advantages

Smooth flat design

The smooth surface looks clean and easy to clean, and the surface is burr-free. The smooth surface will not damage the goods and is not easy to scratch when used.

Ribs on the edges increase the load bearing

The double-reinforced tray with upper and lower layers of ribs is evenly stressed and bears better load.

Pallet face non-slip pad design

Make the surface of the pallet contact with the goods with good friction to prevent the goods from slipping out of the pallet.

Can add steel pipe design

Meet different bearing requirements

Smooth foot design

The smooth foot surface is designed to pass the assembly line, which is convenient and not easy to bump

Smooth Bottom Design

The appearance is clean and easy to clean

The bottom surface is burr-free and not easy to scratch

Nestable Plastic Pallets

The bottom of Nestable Plastic Pallets is a nine-feet structure. The inside of the foot is equipped with horizontal and vertical cross ribs and thickened design. The pallet is not easily deformed after being hit by a forklift. There are water leakage holes at the bottom of the feet, which is easy to clean and will not accumulate water. The feet are tapered to allow pallets to be stacked on top of each other for centralized storage. The pallet occupies a small area and has low transportation costs, which is suitable for the storage of lighter goods and the turnover of unitized logistics transportation.

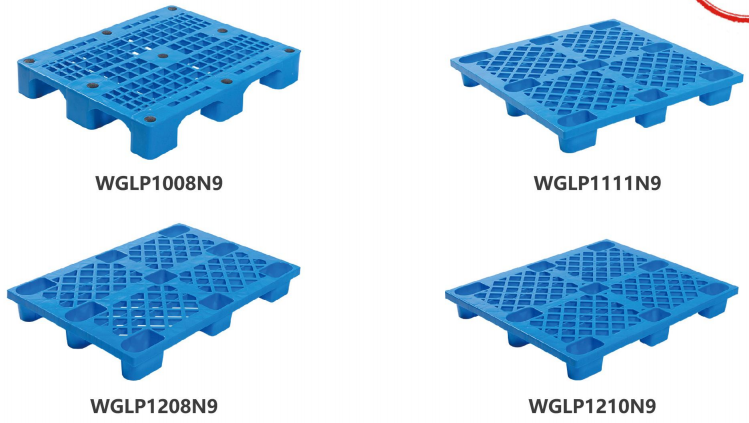

9-Feet Grid plastic pallet

9-Feet Grid plastic pallet |

Names | Numbers of Steel pipe | Dynamic loading(kg) | Static loading(kg) | Dimension (L*W*H/cm) | Forklift | Model |

1008-9 Feet Grid plastic pallet | 0 | 500 | 2000 | 100x80x14 | 4 WAY | WGLP1008N9 |

1111-9 Feet Grid plastic pallet | 0 | 500 | 2000 | 110x110x14 | 4 WAY | WGLP1111N9 |

1208-9 Feet Grid plastic pallet | 0 | 500 | 2000 | 120x80x14 | 4 WAY | WGLP1208N9 |

1210-9 Feet Grid plastic pallet | 0 | 500 | 2000 | 120x100x14 | 4 WAY | WGLP1210N9 |

1311-9 Feet Grid plastic pallet | 0 | 500 | 2000 | 130x110x14 | 4 WAY | WGLP1311N9 |

1210-18 Feet Grid plastic pallet | 0 | 700 | 3000 | 120x100x14 | 4 WAY | WGLP1210N18 |

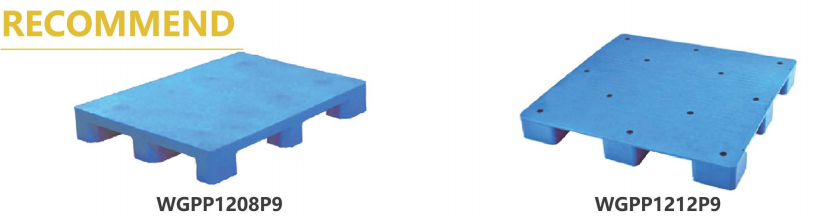

9-Feet Flat plastic pallet

9-Feet Flat plastic pallet |

Names | Numbers of Steel pipe | Dynamic loading(kg) | Static loading(kg) | Dimension (L*W*H/cm) | Forklift | Model |

1111-9 Feet Flat plastic pallet | 4 | 1000 | 4000 | 110x110x14 | 4 WAY | WGPP1111P9 |

1208-9 Feet Flat plastic pallet | 4 | 1000 | 4000 | 120x80x15 | 4 WAY | WGPP1111P9 |

1210-9 Feet Flat plastic pallet | 4 | 1000 | 4000 | 120x100x14 | 4 WAY | WGPP1210P9 |

1212-9 Feet Flat plastic pallet | 4 | 1000 | 4000 | 120x120x14 | 4 WAY | WGPP1212P9 |

1311-9 Feet Grid plastic pallet | 4 | 1000 | 4000 | 130x110x14 | 4 WAY | WGPP1311P9 |

Nestable Plastic Pallets’ advantages

Convenient and fast access from all sides

Plastic pallets are designed with forks on all sides to make the use of space more flexible to maximize the use of warehouse space.

Grid hollow out Rib design

The hollow design on the surface is beneficial to the waterproof and moisture-proof of the goods to ensure that the bottom of the goods is in a ventilated state. The rib design improves the stability of the pallet and also improves the load-bearing capacity of the pallet.

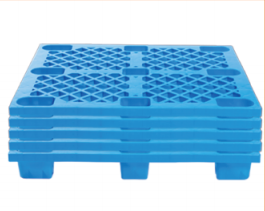

Stackable to save space

Some models can be stacked when not in use to save space.

Pallet foot reinforcement design

Arc design of pallet feet

The interior is equipped with reinforcement ribs, which are impact-resistant and durable

Convenient for forklift use.

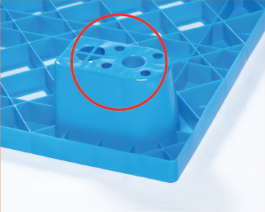

Reinforced leaky design

The bottom of the pallet has a water leakage hole design

Quickly remove stagnant water

Don't worry about water accumulation in the pallet

Meshone-sided light weight design

Lightweight, flexible and easy to carry

Convenient and time-saving operation

Improve the efficiency of cargo turnover.

Features of rackable plastic pallets

1. The stock product of the plastic tray is blue, and other colors such as red, yellow, green, black, gray, white can also be customized, the minimum order quantity is 500 pieces.

2. The product size error of plastic pallets is +3%, the weight error is +3%, the deformation rate of the side wall is ≤1%, the plane deformation of the pallet is not more than 5mm, and the change rate of the diagonal line of the pallet is ≤1%, all of which are within the allowable range of enterprise standards .

3. Adapt to the ambient temperature: -25C to +60C (try to avoid sun exposure and close to heat sources).

4. Raw materials: Ensure the use of new high-quality, high-strength modified PP or HDPE raw materials with good low temperature resistance and weather resistance, and never use recycled materials and recycled plastics or add calcium carbonate.

5. Quality assurance period. Under normal and reasonable use conditions, the product quality guarantee period is three years (36 months). If a damaged product is replaced by a new product of the same model due to damage that affects the reuse of the product, the supplier shall respond to any problems that occur during use. The problem has the obligation to maintain and eliminate it (it belongs to the quality problem of the product itself, except for the damage caused by human factors).

6. After the quality guarantee period or damage caused by human factors, free service is available. If you need to change parts, you will only be charged the cost of the minimum standard. If you need to change products, you will replace three damaged products with a new product of the same model. The freight is borne by the demand side.

7. Under normal use conditions (environment), the minimum service life of the pallet is 5 years. The annual damage rate of the pallet within 5 years is less than 1%. After 5 years, due to the natural aging of the plastic, the annual damage rate of the pallet will be greater than 1%. The number of turnovers of the pallet can exceed 10,000 times (if the pallet is damaged due to severe weather conditions, exceeding the load limit, equipment extrusion or man-made damage, it is not within the above range.)

When purchasing a suitable plastic pallet, the following factors need to be considered

1. The size and structure of the pallet, the packaging specifications of the goods and the way of placing them on the pallet;

2. The situation of pallet loading tools (such as 20 feet, 40 feet containers and trucks, etc.);

3. The situation of the pallet transport tool (such as forklift, stacker, hydraulic truck, etc.);

4. The structure, width and depth of the shelf (such as beam shelf, corbel shelf):

5. The load-bearing capacity, deflection, surface anti-skid coefficient and label position of the pallet, etc.;

6. One-time forming or two-time welding, for the consideration of cost and durability, the tray with one-time forming is preferred;

7. For general-purpose pallet sizes, such as 1210, 1208, 1111, 1311, 1411, 1412, etc., try to choose standardized products.

Plastic Rack Protector

Forklifts, trucks and other equipment will always accidentally collide with the shelf columns when moving goods in the warehouse, which may scratch the paint or bend the columns, causing safety hazards and affecting the service life of the shelves and personal safety. The plastic upright protector is a safety anti-collision device used to buffer the impact force between the shelf column and the handling equipment.

Plastic Upright Protector Parameter |

Product Name | L*W*H(mm) | Material | Weight(g) | Specification | Model |

Small Yellow Plastic Upright Protector | 156*140*100 | PP | 360 | Suitable for column 80-100mm | WGH100-100Y |

Small Black Plastic Upright Protector | 156*140*100 | PP | 360 | Suitable for column 80-100mm | WGH100-100BK |

Large Yellow Plastic Upright Protector | 160*148*100 | PP | 380 | Suitable for column 100-120mm | WGH100-120Y |

Large Black Plastic Upright Protector | 160*148*100 | PP | 380 | Suitable for column 100-120mm | WGH100-120BK |

Racking Plastic Upright Protector

Racking Plastic Upright Protector is made of modified HDPE material by blow molding process, and the inner wall is hollow. Fastened to the post with two nylon straps for easy installation. When the column is impacted by an external force, the outer layer of the corner guard will absorb energy and sag, and can quickly return to its original shape after the impact, which plays a very good role in protecting equipment and personnel.

Rack Plastic Upright Protector Parameter |

Product Name | L*W*H(mm) | Material | Weight(g) | Specification | Model |

Small Upright Protector | 170*110*500 | HDPE | 1200 | Suitable for column 90mm | WGH500-90 |

Medium Upright Protector | 170*110"500 | HDPE | 1200 | Suitable for column 100mm | WGH500-100 |

Large Upright Protector | 170*110*500 | HDPE | 1100 | Suitable for column 120mm | WGH500-120 |

Integrated Rack Protector |

Product Name | L*W*H(mm) | Material | Weight(g) | Specification | Model |

Small Integrated Rack Protector | 120*120*300 | PVC | 600 | Suitable for column 80mm-100mm | WGH300-100A |

Medium Integrated Rack Protector | 120*120*400 | PVC | 800 | Suitable for column 80mm-100mm | WGH400-100A |

Large Integrated Rack Protector | 120*120*600 | PVC | 1200 | Suitable for column 80mm-100mm | WGH600-100A |

Small Rack Protector | 120*120*300 | HDPE | 600 | Suitable for column 80mm-100mm | WGH300-100B |

Medium Rack Protector | 120*120*400 | HDPE | 800 | Suitable for column 80mm-100mm | WGH400-100B |

Large Rack Protector | 120*120*600 | HDPE | 1200 | Suitable for column 80mm-100mm | WGH600-100B |

Plastic Rack Protectors’ feature

Yellow and black collocation, eye-catching warning, beautiful and generous, improve the grade of warehouse.

The installation is simple and fast, and it can be installed by hand and equipped with professional installation tools, without the need for expansion bolts to damage the ground.

The scope of application is wide, and the two specifications of corner protectors can be applied to various shelf columns at home and abroad.

Made of modified PP material, high strength, good toughness and long impact life. It can protect handling equipment and personnel such as shelf columns and forklift stackers.

Application of Plastic Rack Protectors

Building Column Protectors

Warehouse column protectors are specially designed to protect steel platform columns and building support columns. They are made of modified HDPE material blow molding, with a hollow structure and double-layer protection. When the column is hit by equipment such as a forklift, the energy is buffered and absorbed by the sheath, which not only protects the column but also the handling equipment.

Building Column Protectors Parameter |

Product Name | Material | Inside size (cm) | Outside size (cm) | Column protector height(cm) | Model |

Building Column Protector | HDPE | 20*20 | 45*45 | 110 | WGH2020 |

25*25 | 50*50 | WGH2525 |

30*30 | 55*55 | WGH3030 |

35*35 | 60*60 | WGH3535 |

40*40 | 65*65 | WGH4040 |

45*45 | 70*70 | WGH4545 |

50*50 | 75*75 | WGH5050 |

55*55 | 80*80 | WGH5555 |

60*60 | 85*85 | WGH6060 |

65*65 | 90*90 | WGH6565 |